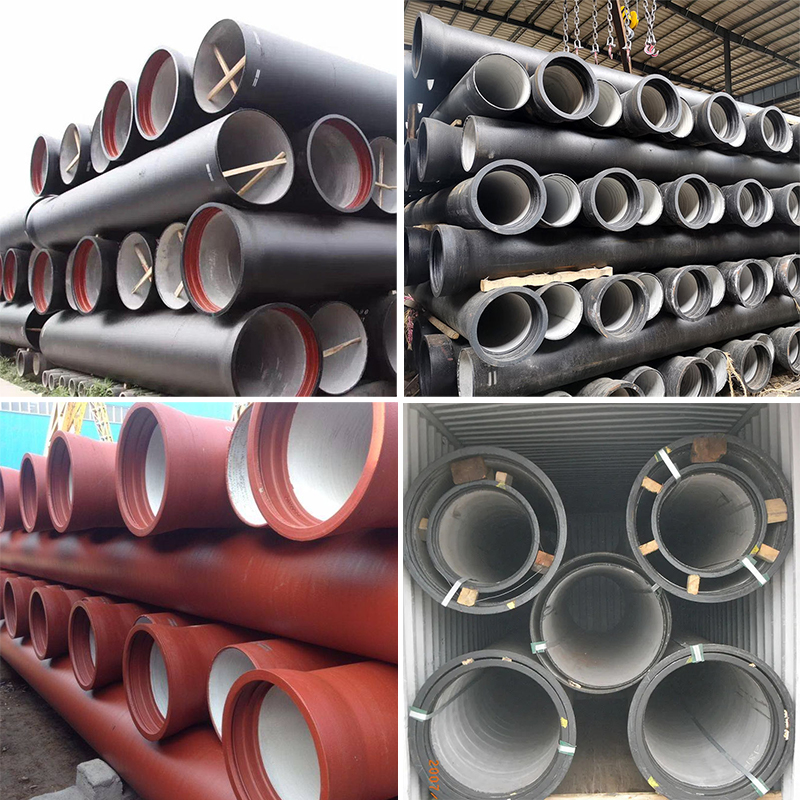

DN80 To DN2600 Ductile Iron Pipe Push On T Type DI Pipes

Brand TOPSUN

Product origin China

Delivery time 30 days

Supply capacity 10,000 tons per year

Our expertise lies in manufacturing a comprehensive range of Ductile Iron Pipes, from versatile DN80 to massive DN2600 lines, all featuring reliable Push-On T Type joints. This robust coupling system ensures rapid, leak-proof installation, significantly reducing labor costs and project timelines. Backed by advanced casting technologies and rigorous quality controls, our pipes deliver superior tensile strength, impact resistance, and longevity, making them ideal for demanding high-pressure applications in potable water transmission and sewer force mains.

With substantial production capacity and strategic inventory management, we maintain ready-to-ship stocks of popular sizes like DN500 and DN600 to expedite your urgent projects. Our annual sales volume, exceeding 10,000 tons globally, is a testament to the market's trust in our product quality and service reliability. This extensive experience is reflected in numerous successful cooperation cases, including recent municipal water supply networks and industrial pipeline replacements across Southeast Asia and the Middle East.

We are committed to continuous technical innovation in pipeline solutions. Our R&D team focuses on enhancing corrosion protection coatings and optimizing the T Type joint design for even greater seismic resilience and installation efficiency. Partner with us for your next project to leverage our proven ductile iron pipe systems, engineered for performance and backed by a global support network dedicated to your success.

Product Name | Ductile iron pipe |

Standard | EN545 /IS02531/EN598 |

Size | Outside Diameter:98mm-1255mmInside Diameter:80mm-1200mmWall Thickness:6mm-153mm Length:6m,cut to 5.7m, or as required. |

Class | K9.K8.C25.C30.C40 |

Surface | External bitumen coating, or as required. |

Internal Coating | a).Portland cement mortar lining b)Sulphate Resistant cement mortar lining c).High-Aluminum cement mortar lining d).Fusion bonded epoxy coating e).Liquid epoxy painting f). Black bitumen painting |

External Coating | a).zinc+bitumen(70microns) painting b).Fusion bonded epoxy coating c).Zinc-aluminum alloy +liquid epoxy painting |

pressure | PN10,PN16,PN25.PN40 |

Standard | AISI,ASTM,DIN,JIS,BS,GB/T |

Delivery times | Delivered within 30 days after the receipt of deposit |

Package | Standard export package, or as required. |

Application Range | Water supply project, drainage, sewage, irrigation, water pipeline |

Ductile Iron Pipe possesses a unique combination of strength, durability, and performance, making it the superior choice for modern pipeline networks. Its key feature is high tensile strength and impact resistance, derived from its spheroidal graphite microstructure, which provides a safety margin far exceeding that of traditional materials. This inherent robustness allows it to withstand severe external loads, pressure surges, and installation stresses.

Furthermore, the pipe offers exceptional corrosion resistance, typically enhanced by cement-mortar lining and various external protection coatings like polyethylene sleeving or zinc-aluminum alloy, ensuring a long service life. A significant operational advantage is its efficient push-on joint system, which enables simple, leak-proof connections without needing complex equipment, drastically reducing installation time and labor costs. These features collectively ensure a reliable, cost-effective, and long-lasting infrastructure solution.

Renowned for its strength and durability, Ductile Iron Pipe is the versatile backbone of modern infrastructure. Its primary application is in potable water distribution networks, where its corrosion resistance and impermeability ensure water quality and system integrity from treatment plants to municipal mains and service lines. Equally critical is its role in sewer and wastewater force mains, handling pressure and resisting the abrasive, corrosive nature of effluents.

Beyond municipal water and sewage, these pipes are indispensable for industrial applications, conveying process water, slurries, and other materials in mining, power plants, and manufacturing facilities. Their robustness also makes them ideal for specialized uses like irrigation systems, fire protection pipelines, and subaqueous installations beneath rivers and canals, providing a reliable, long-term solution for diverse engineering challenges.

Ductile Iron Pipe is a high-performance ferrous pipe manufactured by casting molten iron treated with magnesium to form spheroidal graphite within its matrix. This advanced metallurgical process gives the pipe exceptional strength and durability, combining the corrosion resistance of cast iron with the tensile strength and impact resistance of steel. It is a premier choice for a wide range of pressure pipeline applications.

The pipe is designed for long service life and reliability. It is typically supplied with an efficient push-on T-type joint system, which allows for rapid, secure, and leak-proof assembly. Standard internal protection includes a cement-mortar or polyurethane lining, providing a durable barrier and maintaining water quality. External surfaces are commonly protected with a zinc coating, often supplemented by a bituminous or polyethylene outer layer, offering superior defense against aggressive soils.

Available in a comprehensive size range from DN 80 to DN 2600, our Ductile Iron Pipes are engineered to meet international standards, including ISO 2531 and EN 545. This product is the definitive solution for constructing resilient and sustainable infrastructure networks for potable water, sewage, and industrial fluids, delivering unmatched performance and lifetime value.

CUSTOMERS & MARKET

Q: What's your qualification in this product ?

A: We have been engaged in this industry for decades with seasoned export team. All the product is strictly conformed to the international standard ISO2531:1998,EN545-2002 and other related standard.

Q: How long is your delivery time ?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-30 days if the goods are not in stock, it is according to quantity.

Q: What's your terms of payment ?

A: 30% T/T in advance , balance before shipment or against L/C . And D/P , D/A ,L/C for free options.

Q: What's your trade terms ?

A: FOB , CIF , CFR as per client's requirements.

If you have any other questions , please feel free to contact us.