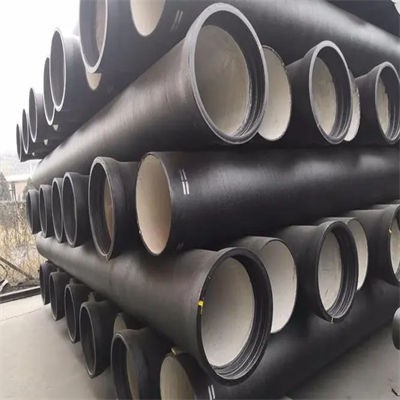

Push On Ductile Iron Pipe Internal and External Protection for di ductile iron Sizes

Brand TOPSUN

Product origin China

Delivery time 30 days

Supply capacity 10,000 tons per year

Push-On Ductile Iron Pipe DN80-2600, zinc+epoxy externals and cement/epoxy internals, ships 48 h from 10 000 t stock.

, powering Manila desalination, Dubai district-cooling and Santiago potable grid.

Robot-sprayed alloy layer, 700 MPa matrix, T-gasket joint 3° flex, PN40 surge 2.5×, trenchless-ready.

ISO2531 EN545/598, NSF, WRAS, 50-year warranty; OEM lengths, coatings, restrained ends available ex-mill.

Product Name | Ductile iron pipe |

Size | Outside Diameter: DN80 - DN2600 Length: 6m, cut to 5.7m, or as required. |

Grade | K9, K10, K11, K12,K9, K8, C25, C30, C40, etc. |

Standard | ISO2531, EN545, EN598, etc |

Surface | External bitumen coating, or as required. |

Internal coating | a). Portland cement mortar lining b). Sulphate Resistant cement mortar lining c). High-Aluminum cement mortar lining d). Fusion bonded epoxy coating e). Liquid epoxy painting f). Black bitumen painting |

External coating | a). zinc+bitumen(70microns) painting b). Fusion bonded epoxy coating c). Zinc-aluminum alloy +liquid epoxy painting |

Quality Control | 100% inspection + professional Lab test |

Certification | ISO, CE, BSI, WRAS,SGS,etc |

Package | Standard export package, or as required. |

Payment | T/T, L/C, Western Union, etc. |

Application | Water supply project, drainage, sewage, irrigation, water pipeline, etc. |

Our push-on ductile iron pipes are engineered for maximum durability and installation efficiency. The innovative push-on joint system, featuring a precision-engineered gasket, ensures a leak-tight seal and drastically reduces assembly time, lowering overall project labor costs.

Long-term performance is guaranteed through our superior internal and external protection. The pipe interior is lined with cement mortar or epoxy, safeguarding water quality, maintaining excellent flow capacity, and preventing biofilm growth. Externally, a robust zinc-aluminum coating with an asphalt or epoxy seal provides unbeatable corrosion resistance, even in the most aggressive soils.

Manufactured to international standards, these pipes offer high tensile strength, excellent impact resistance, and inherent flexibility. The comprehensive size range from DN80 to DN2600 makes them the versatile and reliable choice for a vast array of applications, including potable water transmission, sewer force mains, and industrial pipelines.

Our push-on ductile iron pipes, with their superior internal and external protection, are the preferred solution for a wide range of demanding applications. Their primary use is in municipal potable water distribution and transmission mains, where the certified internal lining safeguards water quality. They are equally critical for sewer force mains, effectively resisting the corrosive effects of hydrogen sulfide.

The robust construction and comprehensive corrosion protection make these pipes ideal for industrial use, including plant process water, slurry pipelines, and mining dewatering systems. Furthermore, their strength and reliability are essential for fire protection systems in commercial and industrial facilities. The availability of a full size spectrum, from DN80 to DN2600, ensures a perfect fit for every project scale, from small residential service lines to large-scale cross-country infrastructure.

CUSTOMERS & MARKET

Q: What's your qualification in this product ?

A: We have been engaged in this industry for decades with seasoned export team. All the product is strictly conformed to the international standard ISO2531:1998,EN545-2002 and other related standard.

Q: How long is your delivery time ?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-30 days if the goods are not in stock, it is according to quantity.

Q: What's your terms of payment ?

A: 30% T/T in advance , balance before shipment or against L/C . And D/P , D/A ,L/C for free options.

Q: What's your trade terms ?

A: FOB , CIF , CFR as per client's requirements.

If you have any other questions , please feel free to contact us.