-

Push On Ductile Iron Pipe Internal and External Protection for di ductile iron Sizes

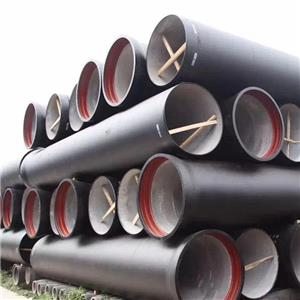

Push-On Ductile Iron Pipe DN80-2600, zinc+epoxy externals and cement/epoxy internals, ships 48 h from 10 000 t stock. , powering Manila desalination, Dubai district-cooling and Santiago potable grid. Robot-sprayed alloy layer, 700 MPa matrix, T-gasket joint 3° flex, PN40 surge 2.5×, trenchless-ready. ISO2531 EN545/598, NSF, WRAS, 50-year warranty; OEM lengths, coatings, restrained ends available ex-mill.

Internal Protection Ductile iron pipe External protection Ductile iron pipe push on ductile iron pipeSend Email Details -

K-Type Push On Ductile Iron Pipes Featuring Advanced Internal External Protection for Longevity DI pipes

Our K-type and push-on Ductile Iron (DI) pipes are engineered for high-performance applications in municipal water supply, sewer systems, and industrial fluid transport. Their robust design ensures reliable service in demanding environments, supported by proven success in numerous global infrastructure projects. Key features include exceptional pressure rating and leak-proof joints, making them a preferred choice for contractors and engineers seeking durability and efficiency in pipeline installations. Internally, our DI pipes are protected with advanced cement-mortar or epoxy linings, preventing corrosion and ensuring water quality compliance. Externally, they feature durable polyethylene sleeving or zinc-aluminum coatings combined with bitumen for superior resistance to aggressive soils and harsh environmental conditions. Our continuous R&D focuses on enhancing these protective technologies, resulting in longer service life and reduced maintenance costs for our clients across various international projects. Backed by strong production capabilities, we maintain a significant inventory of DI pipes to meet urgent project demands and large-scale orders. Our manufacturing plants utilize state-of-the-art automation and strict quality control processes, enabling us to achieve substantial annual sales volumes while consistently meeting international standards. This production strength, combined with our extensive global distribution network, ensures timely delivery and reliable support for both stock items and customized pipe solutions.

K type Ductile Iron pipe Internal Protection Ductile iron pipe External protection Ductile iron pipeSend Email Details