Ductile Iron Vs. Steel Pipe: How To Make The Best Choice

When engineering a pipeline project, material selection determines the longevity and profitability of the infrastructure. A common debate arises when comparing DI pipe (Ductile Iron) against its primary competitor, steel.

In this guide, Topsun compares the two materials across critical categories: design safety factors, long-term energy costs, corrosion resistance, and ease of installation. Here is why ductile iron material often emerges as the superior investment.

Design Safety Factors

The design philosophy behind ductile pipe is inherently conservative, prioritizing safety and longevity. Decades of reliable service underscore its success. The design calculations typically follow the ANSI/AWWA C151/A21.51 Standard.

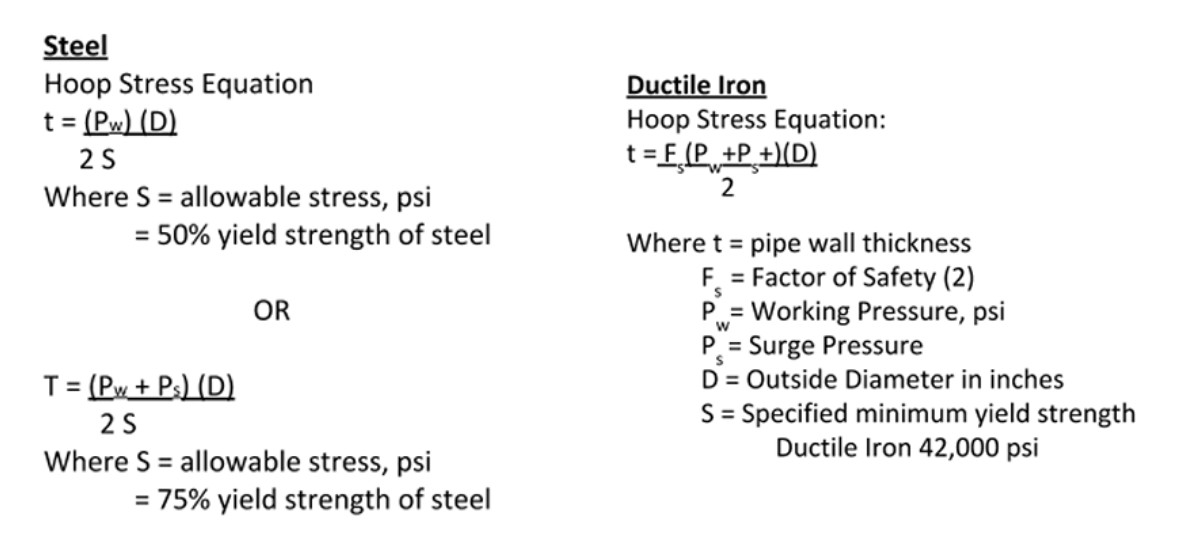

The most glaring difference lies in the safety factor. DI piping is designed with a safety factor of 2.0. In contrast, steel pipe safety factors range from 1.33 to 2.0, depending on the percentage of yield strength utilized.

When calculating thickness for a 24-inch water line operating at 150 psi, steel pipe allows for significantly thinner walls (approx. 0.086 to 0.095 inches). Ductile iron requires a much robust 0.157 inches, with standard Class 200 pipe providing a minimum of 0.24 inches. This extra thickness provides a "comfortable" margin of error against external loads and pressure surges that thin-walled steel simply cannot match.

Let’s Talk Cash: Energy Efficiency

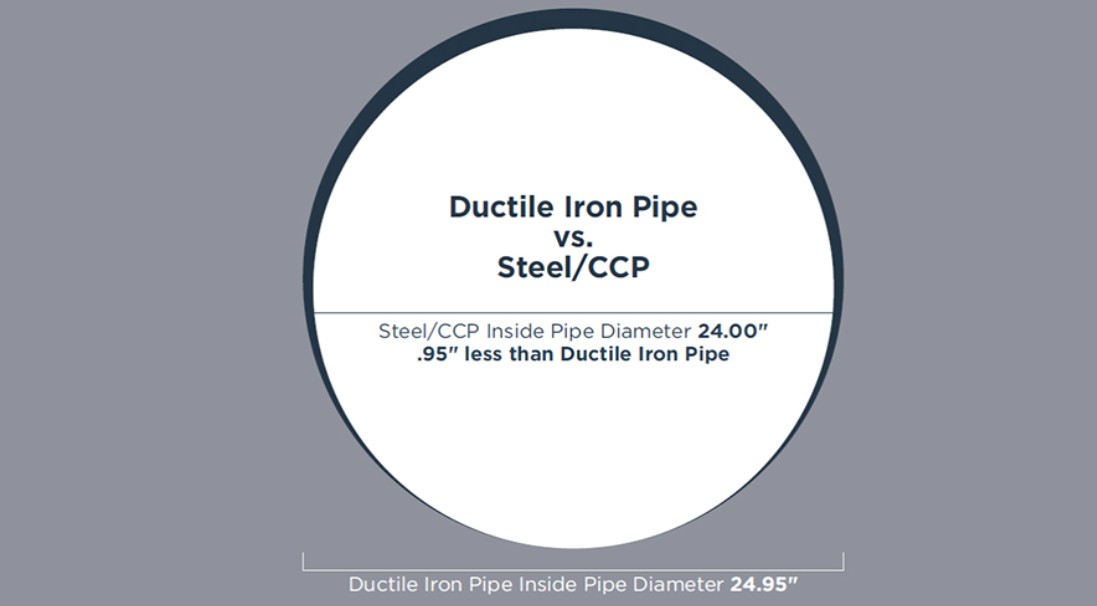

Beyond the initial purchase price, the long-term operational cost of a pipeline is heavily influenced by pumping energy. Due to its larger actual inside diameter (ID) compared to nominal steel pipe sizes, DI pipe offers less flow resistance.

Consider a 2,000-foot transmission line (24-inch diameter) operating continuously:

| Metric | Ductile Iron | Steel |

|---|---|---|

| Actual ID (inches) | 24.95 | 22.94 |

| Flow Velocity (ft/sec) | 5.0 | 5.9 |

| Annual Pumping Cost | ~$9,650 | ~$14,540 |

Using ductile iron can result in annual savings of nearly $5,000 in energy costs alone. Over a 50-year lifespan, this return on investment is substantial.

Corrosion and Protection

Ductile iron material has a unique advantage in corrosion control. During manufacturing, an oxide layer forms on the pipe surface, providing a base level of protection. For aggressive soils, the industry standard solution is Polyethylene Encasement (often referred to as V-Bio®).

This loose-fitting sleeve inhibits microbiologically influenced corrosion and galvanic corrosion. It is cost-effective and easy to install in the field. Conversely, steel pipe requires expensive bonded coatings. These coatings are fragile; handling a heavy steel pipe without damaging its coating is difficult. Any scratch or void in a steel coating becomes a hotspot for rapid corrosion, requiring expensive field repairs before burial.

Additional Cathodic Protection Issues

One of the hidden costs of steel is the need for active Cathodic Protection (CP) systems. Because steel joints are welded and continuous, the entire pipeline acts as an electrical conductor, increasing the risk of electrolysis.

DI pipe joints are rubber-gasketed and discontinuous. This electrical isolation prevents long-line corrosion cells from forming. Consequently, ductile iron rarely requires the maintenance-heavy CP systems that are standard for steel pipelines. This further reduces operational expenditures (OPEX).

Installation Factors

Weather is the enemy of construction schedules. Steel pipe requires welding, which essentially stops whenever it rains, snows, or gets too cold. DI piping uses push-on joints that can be assembled in virtually any weather condition—rain, sleet, or freezing temperatures.

Furthermore, efficiency matters. Ductile iron typically comes in 18 to 20-foot lengths, whereas steel comes in 40 to 50-foot sections. While longer pipes seem faster, they are unwieldy and require large machinery. A crew can often install four joints of 24-inch ductile iron (72 feet) in the time it takes to weld and inspect one 40-foot steel joint.

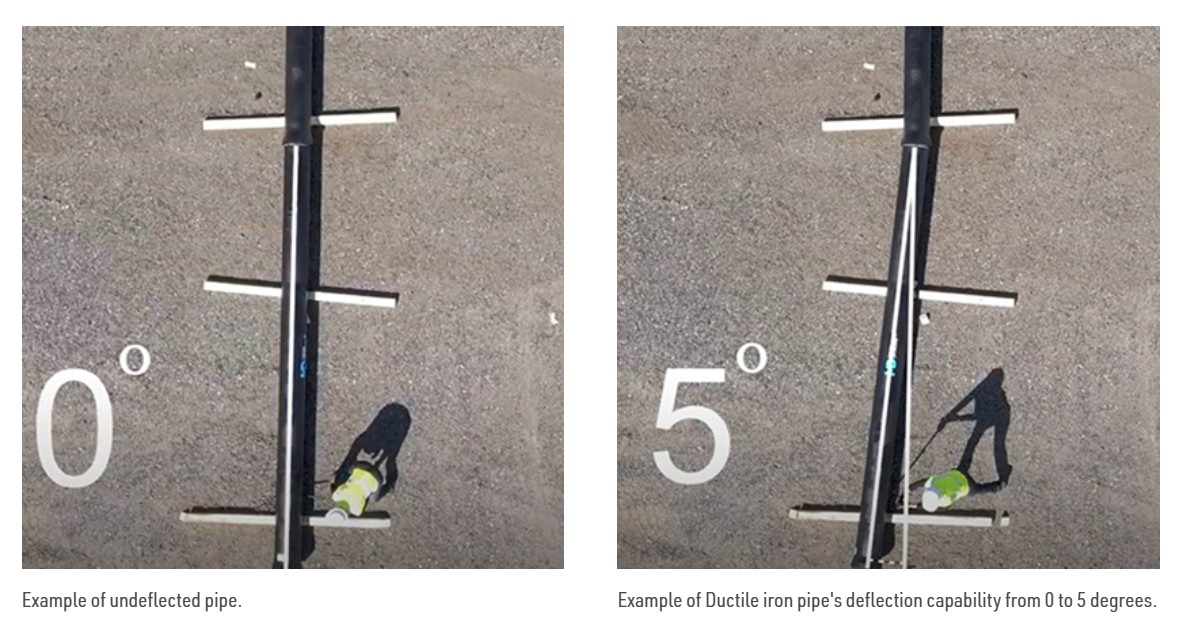

Deflection Capability: The shorter lengths of ductile iron allow for joint deflection (typically up to 5 degrees). This flexibility allows the pipeline to curve around obstacles or follow the terrain without needing expensive custom fittings. Steel pipelines are rigid and unforgiving.

Summary

When comparing ductile iron vs steel pipe, the choice becomes clear for most waterworks applications. Ductile iron offers a robust safety factor, lower pumping costs, simpler corrosion protection, and all-weather installation capabilities. It is a sustainable product made from recycled content that is built to last for generations.

While steel has its niche in ultra-high-pressure applications, for municipal water and wastewater infrastructure, ductile iron remains the gold standard.

Need Assistance with Your Waterworks Project?

Navigating technical specifications can be complex. If you need a reliable ductile iron supplier, Topsun is here to help. Our team brings decades of experience in pipeline construction and operation.

As one of the leading ductile iron pipe manufacturers globally, we assist water professionals from design to installation. Contact us today to discuss your next project.